Our Infrasturcture

Our Infrastructure, Your Guarantee of Quality

At DND Machinery Pvt. Ltd., we prioritize quality with advanced infrastructure and cutting-edge technology. Our skilled team ensures precision and reliability through rigorous quality control at every stage of production, delivering durable and high-performance machinery.

- Manufacturing Unit

- Quality Control Unit

- Sales and Marketing Division

- Administrative Department

Get In Touch

Get in Touch for Inquiries & Support

At DND Machinery Pvt. Ltd., we value clear communication and are here to assist you with any questions or inquiries. Whether you need more information about our products, require technical support, or have specific requests, our team is ready to help. Get in touch with us today, and we’ll ensure you receive prompt and reliable assistance.

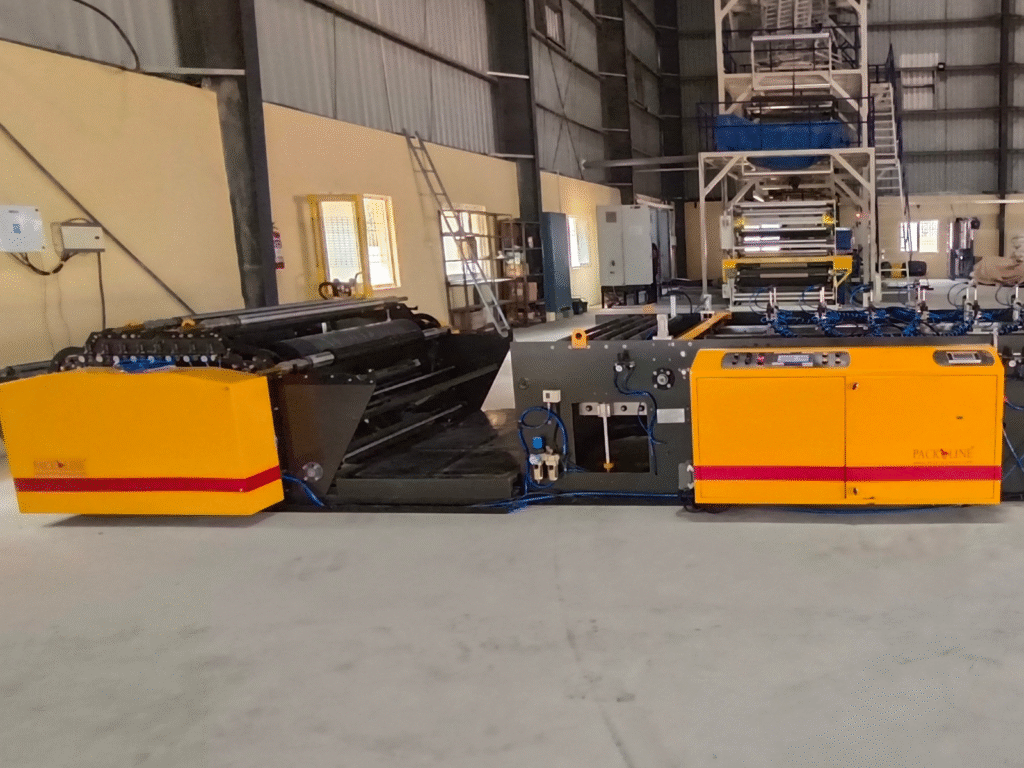

Some Glimpse - Our Infrastructure

Strong Infrastructure, Stronger Results

Explore the strong foundation behind DND Machinery Pvt. Ltd. Our state-of-the-art infrastructure is designed to support efficient, high-quality manufacturing. From advanced machinery and dedicated workspaces to organized warehousing and quality control labs, every corner of our facility is built for performance. Our well-planned infrastructure ensures smooth operations, consistent output, and the ability to meet growing industry demands with confidence.

Manufacturing Unit

Precision Engineering: Use of high-precision tools and processes to ensure tight tolerances and superior product quality.

Lean Manufacturing: Application of lean principles to minimize waste, reduce lead time, and optimize production efficiency.

Product Traceability: Each product is tracked through every stage of production for transparency and quality assurance.

Flexible Production Lines: Ability to quickly adjust production lines to meet changing demands and new product designs.

Quality Control Unit

In-House Laboratory: Fully equipped laboratory for detailed material and product testing.

End-to-End Quality Assurance: Quality checks conducted from raw material selection through to final product inspection.

ISO Certifications: Adherence to global standards, with certifications like ISO 9001 for quality management and ISO 14001 for environmental management.

Non-Destructive Testing (NDT): Use of NDT methods to inspect critical components without damaging them, ensuring longevity and performance.

R&D Unit

- Collaborations with Industry Experts: Partnering with universities and experts for cutting-edge developments in machinery technology.

Proactive Market Research: Regular analysis of market trends and customer feedback to guide product development.

Patented Technologies: Development and implementation of unique patented technologies for enhanced product functionality.

Focus on Automation: Research into new automation technologies to improve machine efficiency and reduce labor costs.

Infrastructure Unit

Real-Time Monitoring Systems: Integration of IoT (Internet of Things) devices for monitoring machinery performance and facility conditions in real time.

Modular Facilities: Design of scalable, modular infrastructure to quickly adapt to increased production needs.

Water & Waste Management: Advanced systems to manage water usage and waste disposal, ensuring sustainability.

Disaster Preparedness: Robust contingency planning and infrastructure to withstand unforeseen events, ensuring production continuity.

Customer Service Unit

24/7 Support Availability: Round-the-clock technical support to address urgent issues and reduce downtime.

Remote Monitoring Services: Offering remote diagnostics and support to troubleshoot and resolve issues quickly.

Maintenance Contracts: Customized maintenance plans to ensure long-term performance and avoid unexpected breakdowns.

Parts Inventory: A well-stocked inventory of spare parts to ensure fast replacements and minimize machine downtime.