What Makes Our Side Sealing Machine a Top Choice ?

- High-Speed Production: Delivers up to 300 strokes per minute, ensuring rapid and efficient bag production.

- Versatile Film Compatibility: Works with various films including LDPE, HDPE, PP, and BOPP.

- Customizable Attachments: Equipped with multiple attachments for diverse bag types:

- Bottom gusset

- Inside or outside lip former

- Handle punch

- Pre-sealer

- Lateral sealer

- Perforation

- Tape applicator for courier bags

- Optional Attachments: Enhances machine functionality with:

- Various punches, including wicket punches

- Edge guide system

- Manual powder brake

- Film folding device

- Ultrasonic knurling

- Header sealer

- Durable Construction: Built with a 12 mm M.S. plate for structural integrity, powder-coated for durability, and features hard-anodized aluminum guide rollers.

- Comprehensive Accessories: Includes a static eliminator, center and side slitter attachments, Seal-King tape attachment, and staking tray.

- Dimensions and Weight: Measures 2800L x 1400W x 1800H mm with an approximate weight of 550 to 600 kg

- This is highly versatile and can convert various jobs.

- Materials that can run on the machine BOPP, LDPE, HDPE, PP.

- Various optional attachments for a multipurpose application such as:

- Various Punches including Wicket Punches, Edge Guide System, Manual Powder Brake, Film Folding Device, Ultrasonic Knurling, Lip Formation, Bottom Gusset, Header Sealer, Pre Sealer, Tape Applicator.

This machine combines high-speed performance with customizable features, making it a versatile and reliable choice for various bag-making needs.

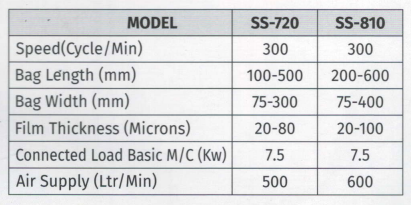

| MODEL | SS-720 | SS-810 |

|---|---|---|

| Speed (Cycle/Min) | 300 | 300 |

| Bag Length (mm) | 100-500 | 200-600 |

| Bag Width (mm) | 75-300 | 75-400 |

| Film Thickness (Microns) | 20-80 | 20-100 |

| Connected Load Basic M/C (Kw) | 7.5 | 7.5 |

| Air Supply (Ltr/Min) | 500 | 600 |

We’re Here for You—Even After the Sale!

Providing Full Range of High Quality Product & Service Solution

For inquiry+91 78782 54733

Contact UsNeed Help? Find Answers Here

Find answers to the most common questions about our products, solutions, and services. Whether you’re curious about our offerings, need help with a specific issue, or want more information, our FAQ section is here to assist you.

Our Side Sealing Machine can handle up to 300 strokes per minute, allowing for high-speed and efficient bag production.

It’s versatile and works with LDPE, HDPE, PP, and BOPP films, making it suitable for a wide range of bag types.

Absolutely! It features a Mitsubishi touch screen panel for intuitive control and easy operation. We also provide training to get you up and running smoothly.

We offer complete after-sales support, including maintenance services, spare parts supply, and technical assistance to ensure the optimal performance of your machinery.

You can enhance the machine’s functionality with attachments like wicket punches, edge guides, and a film folding device, among others.

The machine is built with a 12 mm M.S. plate for durability, and it features hard-anodized aluminum guide rollers and a powder-coated finish for long-lasting performance.

Request A Quote

Need more details? Fill out the form, and we’ll be in touch soon